Innovative Memory Test

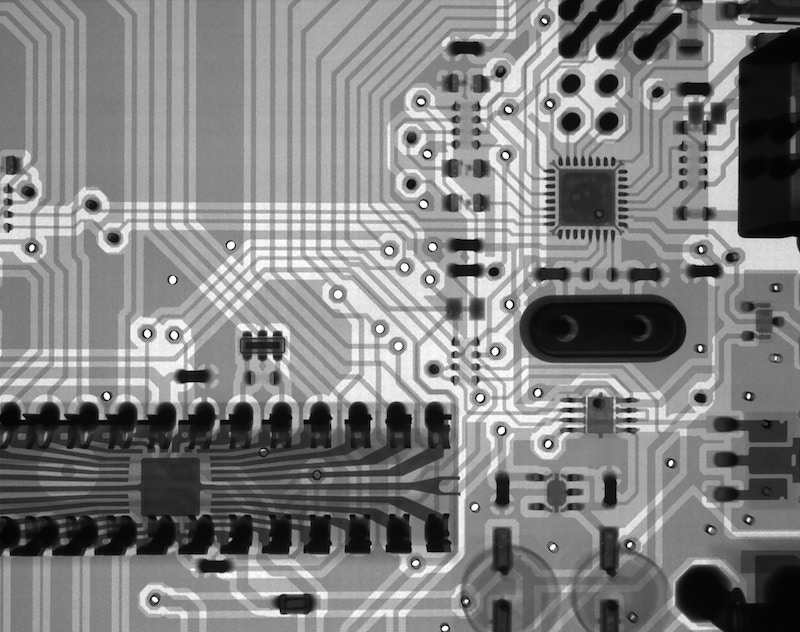

Oulong Technology has developed a proprietary application test methodology for DRAM components. In the future we will extend this technology to FLASH and other semiconductor products. Instead of using costly DRAM production test equipment and fixtures our approach is focused on application motherboards and micro climate chambers on a proprietary DIMM module like fixture.

Our main target is not to provide another low cost, low quality test methodology! We do not believe anymore in the use of high cost production test equipment for burn-in, core- and speed-test due to its limitations like unrealistic low noise and low frequency environment.

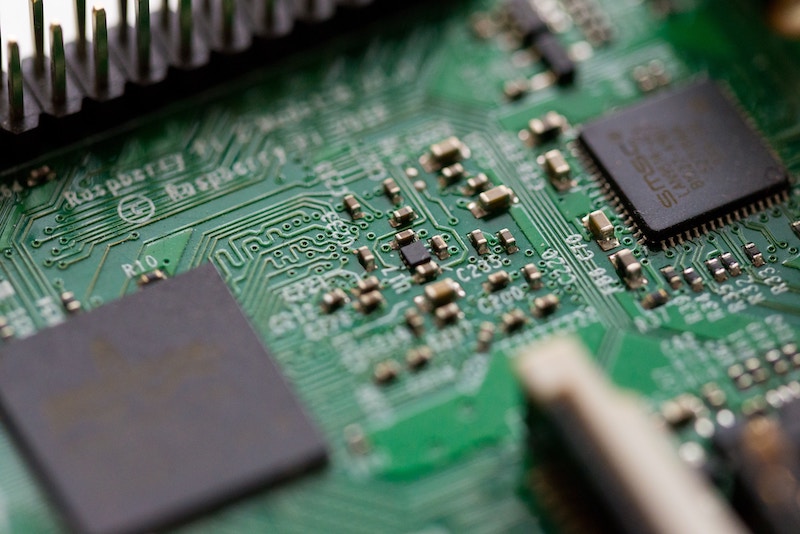

Real Application Environment At Speed Delivers Higher Quality Memory Products.

It is quite common these days to have DRAM components which are perfectly pass in production test but show single cell or other fails in real application use at customer. Our approach provides are more realistic test environment for DRAM components and therefore delivers higher quality products to our customer. In addition, our approach does not need high invest for production tester and handler toolings (hifixes and change kits), therefore enabling small volume specialty products in less than 1-2 months, with testing temperatures from -50C to 150C. We can effectively do own package size solutions for satellite and other special application customers where only a total production volume of 20-30k components will be needed over product life time.